Company Profile

Flow of Manufacturing

MACHINEPRO has skilled engineers for each process ? mechanical design, electrical control design, parts processing and facility assembly. This means that we are able to handle jobs from small projects involving various specialized machines to large projects involving automatic assembly lines that accurately capture your needs.

1. Specifications Meeting

We will meet with you to discuss the facility capacity, technologies, size and delivery schedule you require based on your facility specifications and product drawings.

- TEL

- 0563-65-0125

- FAX

- 0563-65-0126

- Reception hours:

- 8:30~17:30

- Closed:

- Saturdays and Sundays

2. Conceptual Drawing and Quotation Preparation

We will propose the optimal production facilities with great cost performance utilizing our advanced technological strengths and accumulated expertise based on what you say in the specifications meeting.

3. Mechanical Design and Electrical Control Design

Great facilities can only come from great designs. We will meet with you about the details of your facilities while adopting the opinions of mechanical designers, electrical control designers, parts processors and assemblers. We will then design your highly efficient facilities with high quality.

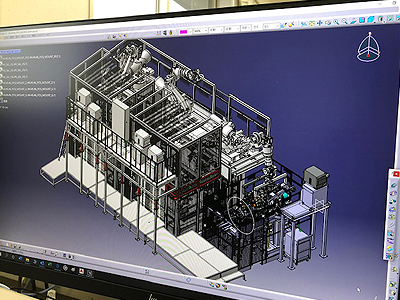

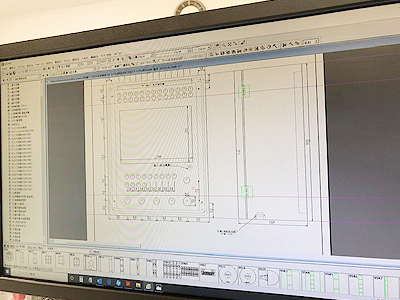

Mechanical Design

We can reduce defects to the minimum prior to manufacture by designing your facilities using the latest 3D CAD and 3D robot simulators.

Electrical Control Design (Hardware and Software)

We design control devices and circuits based on the control method and control flow.

4. Parts Arrangement (Parts Processing and Purchased Goods Arrangement)

We manage costs and delivery schedules. We place orders so that we can meet deadlines at an appropriate price. We pay strict attention to precision in parts processing. We manufacture by allocating this work to in-house processing and partner processing companies inside and outside Japan according to the cost and delivery schedule. We measure all processed goods.

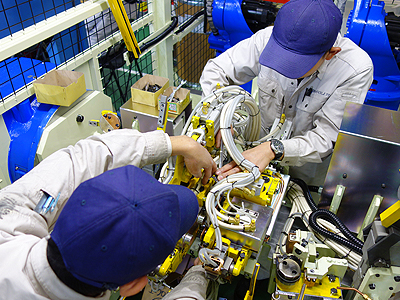

5. Assembly and Control Panel Manufacture

We faithfully assembly your facilities based on the assembly drawings. We also measure the static accuracy at all the necessary places.

6. Operation Adjustment

We input an electrical control program and then check the operation of the facility using your actual work. We will make adjustments to satisfy all your requirements (e.g., cycle time and product quality). We will repeatedly confirm that there are no defects in any place on your facility and that it is operating properly.

7. Inspection in Your Presence (Facility Function Check)

You can check whether the completed facility operates according to your specifications from a functional and safety standpoint here.

8. On-site Installation and Startup

We will provide support with the installation, restoration and leveling of your facility in your factory regardless of whether in Japan or overseas. We will check operation and perform a test run. We will then make final adjustments to your facility.

9. Customer Service

We will provide prompt follow-up in the event a defect arises after delivery. In addition, we will remodel your existing facility in response to your requests and need for improvements.

- TEL

- 0563-65-0125

- FAX

- 0563-65-0126

- Reception hours:

- 8:30~17:30

- Closed:

- Saturdays and Sundays